That’s an inquiry that would take two or more university degrees to properly address and I don’t have any. I can give you an opinion but you need at least Civil Engineer and an architect to get to the bottom of it.

I haven’t done my homework on this thread as to why they would use structural steel in that one area. Long spans for open spaces are one common reason for using steel instead of reinforced concrete. You can span greater lengths with steel having less material volume. Sometimes it’s just easier to use steel compared to very complex concrete formwork in a tight space. Maybe it is for the look of things, I’m just guessing. Maybe someone actually qualified to address the structural steel question can take it from here.

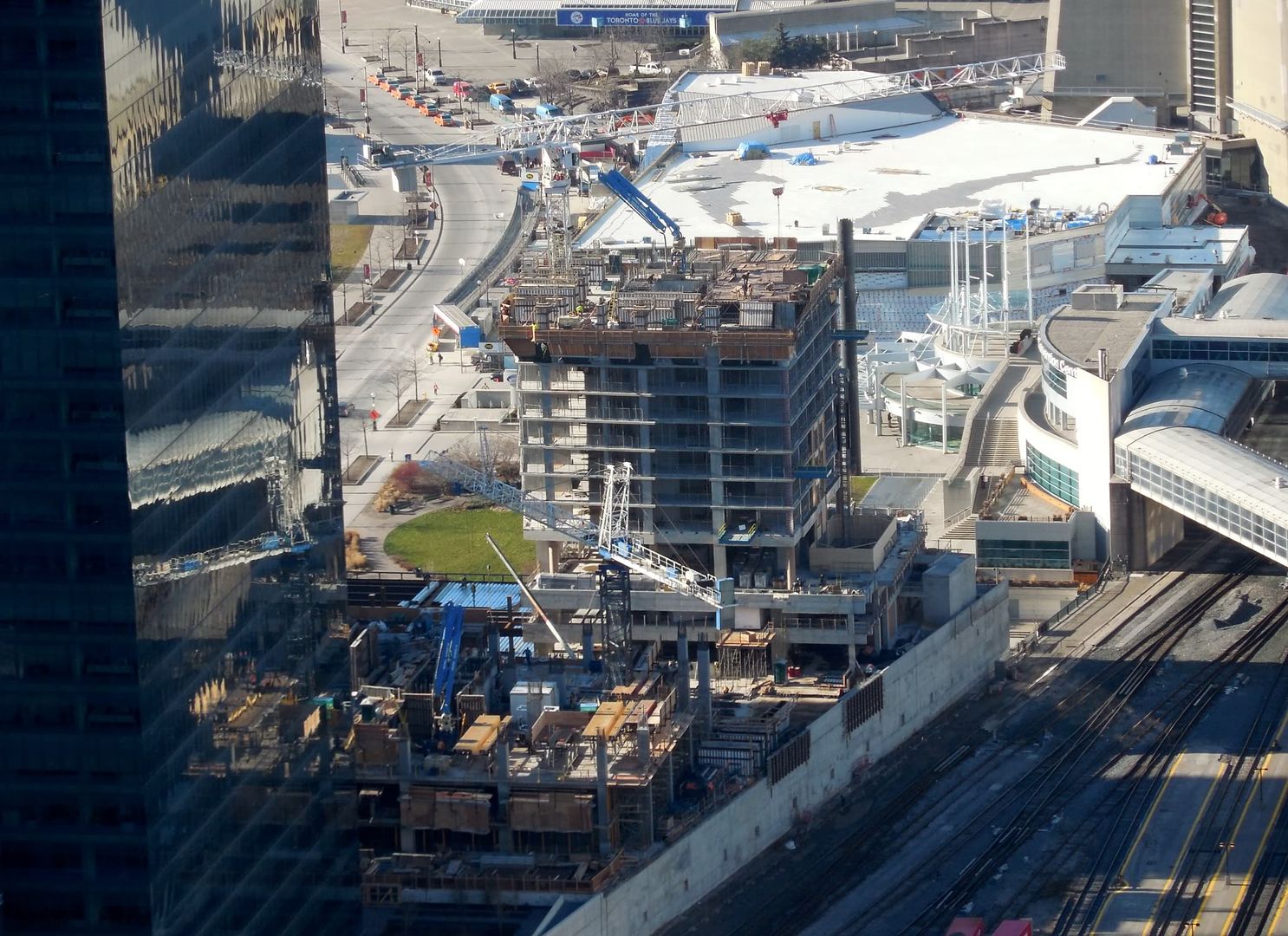

As for the concrete part of your question, I can address some of that using one of the Southcore projects closest neighbours as an example. I took the picture below and selected the visible portion of the CN Tower to demonstrate. I would assume it happens every summer but certainly last summer workers on swing stages could be seen inspecting and repairing the exterior concrete surface of the CN Tower. The crop/zoom picture clearly shows patches on the surface of the concrete and some major horizontal patches along nearly equidistant lines up the tower.

I can speculate and I emphasize speculate that the larger horizontal patches are at a point along the construction of the tower that required changes to the formwork to accommodate the smaller size of the tower higher up. These changes would have taken enough time to interrupt the “monolithic†aspect of concrete placement. Changing the slip form to make it smaller could have stopped concrete placement long enough to cause what’s called a “cold joint†where the concrete on one side of the stoppage was too hard to bond monolithically with the fresh concrete added after the forms were reduced in size.

In any case, this patching can clearly be seen at very regular intervals and there is an explanation but I am just making an educated guess. The patching is done by cleaning away all loose material from the patch area and applying a bonding agent before putting the concrete patch material (grout) in position. The grout mix design is very specific for different applications.

The reason they are so carefully maintaining a surface of the CN Tower is to prevent water from reaching the reinforcing steel within the concrete. Steel exposed to oxygen will rust, the rust is bigger than the steel it is replacing (added oxygen molecules), the rust forces the concrete apart like a tree root causing the concrete to spall or break away starting near the surface. If this maintenance is not ever done you could be looking at that 60 year life span as you suggested, much like another close neighbour to Southcore, the Gardiner Expressway. Bad examples like the

Gardiner and the

Elliot Lake Algo Mall are out there for sure but that is not the plan. Quality concrete properly maintained is expected to last much longer than 60 years. In fact, there are many examples of reinforced concrete structures from the Second World War in very good condition without ever having had any maintenance at all.

This “

Dead Giant on the Beach†at Cape May in New Jersey was built by the US Army Corps of Engineers early into of the Second World War. Today’s modern concrete mix designs and improved quality control is allowing for stronger and lighter product. This is permitting many ambitious projects like the

Burj Khalifa in Dubai that are expected to have life spans greater than 60 years. The Hoover Dam has been in use since 1936 and they are counting on many many more years of service from it.

I can assure you, the collective “they†are hoping for much more than 60 years from the Southcore buildings or the CN Tower for that matter. The acknowledged oldest reinforced concrete building, The Ward House in Port Chester, NY, was built in the 1870’s., and the Ingalls Building in Cincinnati, Ohio, built in 1903, was the world's first reinforced concrete skyscraper (15 stories). Both buildings are still in use today.

A few notes about concrete;

Concrete is not poured; it is placed, as close as possible to its final destination.

Concrete does not dry, it hardens. Water reacts chemically with the cement causing it to bond with adjoining particles (sand and stone, called aggregate) creating concrete. If the concrete were to “dry†and all of the water was to leave the mix, too much volume would be lost and the concrete would become unstable.

The water/cement ratio in a concrete mix is one of the most important factors in the overall strength of the product. Too much water in the mix effectively causes too much space between particles for the best bond. Modern concrete uses add mixtures know as plasticizers or “Super P†to mimic additional water in the mix. These additives allow for a more plastic or sloppier mix for use in long pump runs and concrete forms with a lot of rebar preventing complete consolidation of the concrete.

In my opinion proper use of concrete as a building material will yield buildings with great longevity requiring little or no maintenance. As long as accepted construction standards are properly applied and water is not permitted contact with reinforcing steel, concrete buildings can last for hundreds of years.